By Lisa Thibodeau

For countless companies in Kanata North and around the world, one of the first steps to bringing high-tech products to market – everything from telecommunications gear to aerospace components – has long been a testing lab on Teron Road.

The exterior signage, as well as the facility operator, has changed several times over the past two decades. But there’s been a constant during that same time period: A core group of skilled technicians who have been with the testing lab since its early days and helped it evolve and remain a world-class facility.

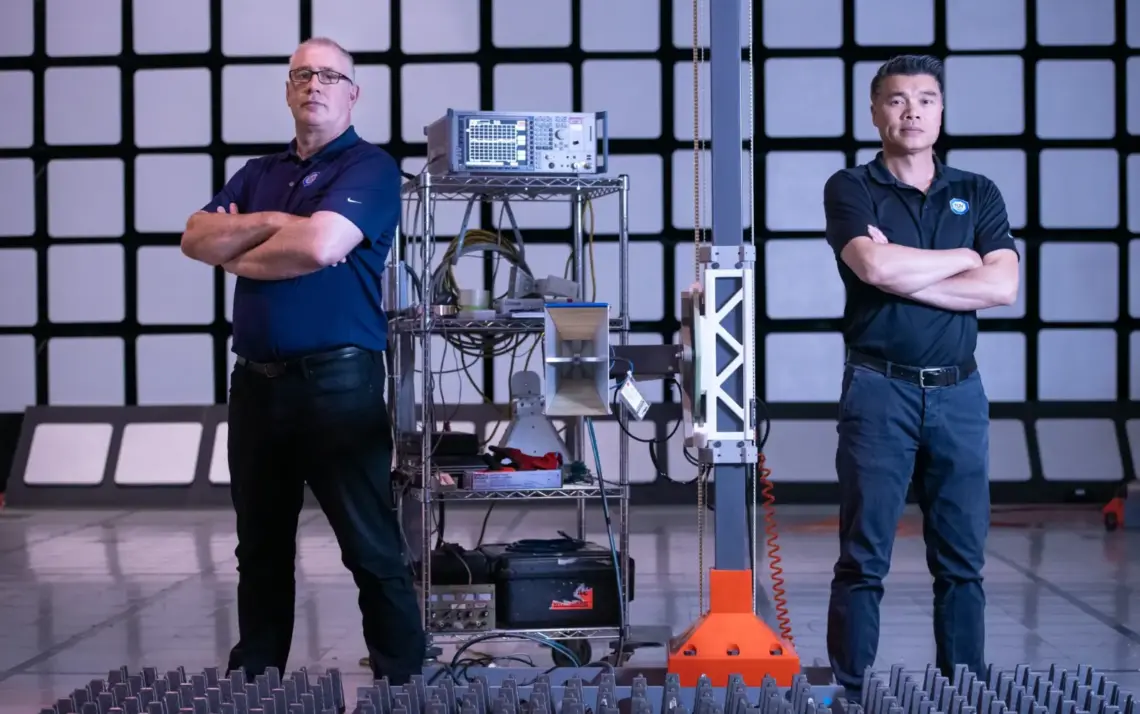

“We support each other,” says test technician Martin Lee. “The people are very important in making this business operate – it’s not just a bunch of machines that get the work done.”

Inside its walls, skilled workers put products developed by other companies– such as fibre optics and consumer goods including laptop displays – through a series of rigorous tests on vibration tables, radiation vaults and in temperature-controlled chambers.

Many of the products tested at the facility may be transported over rough terrain, or exposed to extremely high or low temperatures, says Peter Connolly, an account executive at TÜV SÜD.

By pushing products to their breaking points, TÜV SÜD is helping clients identify any weaknesses in order to make them better suited to withstand use, he adds.

A NEW CHAPTER

TÜV SÜD may be new to Ottawa, having taken over the facility in 2018, but many of its Kanata employees have deep roots in the local tech sector. Several previously worked for Nortel, which built the Teron Road location in 1999.

The facility has since changed hands four times, keeping employees such as lab manager Stephen Tippett engaged with cutting-edge technology and a strong workplace culture.

“Pretty much everybody stayed on board,” he says, estimating that about 80 per cent of the roughly 15 employees have been with the facility since “the early days.”

A portion of the Nortel team remained when the facility was acquired by C-MAC, a Canadian electronic testing facility based out of Sherbrooke, Que. Other workers, such as Lee, left during ownership changes but found their way back.

Lee returned in 2003 and has remained ever since, in large part because of the culture within the facility. The facility continued building and testing products but changed hands again in 2003 when it was bought by Solectron, taking the existing staff with it.

Tippett and Lee continued their work certifying products through another acquisition by Singapore-based Flextronics in 2008.

AUTONOMOUS VEHICLES

When Flextronics outgrew the facility and moved up the road, it opened the door to TÜV SÜD to enter the Kanata North market.

Throughout the changes in ownership, the lab’s employees maintained the client relationships built over the years.

“The lab is scaled and equipped and accredited in a way that aligns with the things these companies need,” says Tippet, who credits the Kanata tech park’s close-knit community for keeping employees and customers engaged throughout the years.

“It’s the perfect size and shape for Nokia, Ciena, Ericsson – those (firms) still have a lot of Nortel DNA in them because they acquired products from the breakup of the company.”

TÜV SÜD is finishing a full renovation of the space. While Nortel spared no expense in future-proofing the building – its largest lab has been used nearly every day since its inception in 1999 – there are new additions being made to further update it.

The company is expanding its work in wireless and Bluetooth connectivity testing to prepare for advancements in autonomous vehicles. The company purchased new wireless and radio frequency testing equipment, turning it into a tier-one wireless testing laboratory.

“Having new industries in the marketplace is pretty exciting,” says Lee. “Bringing in new customers, testing cars … there’s a lot of industries here in Ottawa and we’re hoping we can help them all.”

A new lab is also being built to allow for more testing of smaller products. While the larger lab often deals with month-long tests for large telecom or aerospace equipment, the new space turns around tests much quicker, allowing products to get to market

faster.

While the products being tested within the facility may be constantly evolving, its longtime employees say there has been a sense of consistency in other areas of their work.

“There is an overarching culture here,” Tippet says. “We’ve been owned by different companies, from different countries and different cultures, but what we do has always remained the same.”