Ranovus Inc. has mastered many difficult technology challenges to become a leading provider of optical interconnectivity solutions and co-packaged optics for artificial intelligence and machine learning (AI/ML) in data centre applications.

“We do it with a very innovative, and very power efficient and cost-effective technology,” says Hamid Arabzadeh, Ranovus’ chairman and chief executive officer. “We source a quantum dot laser from the Canadian Photonics Fabrication Centre (CPFC) at the National Research Council Canada (NRC).”

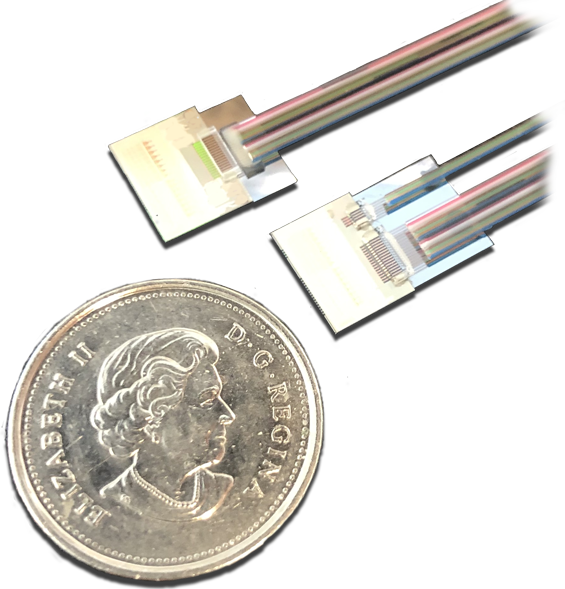

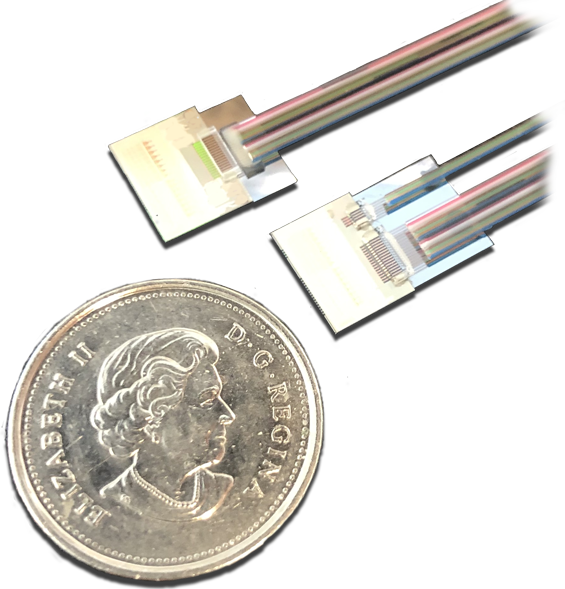

The source of that technology is a multi-wavelength laser source single chip.

“Think of each of these wavelengths as being lanes of a highway, and in a single fiber you can have many lanes. In each lane you have cars that go at a very high speed. This allows you to put a lot of cars in that single fiber,” explains Arabzadeh.

Ranovus spent tens of millions of dollars in the NRC-CPFC facility to enable this technology to be advanced from a research phase and then sampled into something that could be production-ready, qualified and rolled out into the market, says Arabzadeh.

In 2018, Ranovus began examining the next generation of interconnect for inside the data centre that would be able to connect servers, GPUs, CPUs and memory together. The company also studied how to find a very power-efficient and cost-effective way of doing so. Instead of using traditional copper, they discovered this could be accomplished in fiber optics using optical technology.

Furthermore, interconnectivity using copper is reaching its limit, says Arabzadeh. “You cannot put multiple cars and multiple lanes on the copper highway, but on fiber, you can. So that’s what we got into,” he explains.

CPFC manufactures the Ranovus designed lasers. The wafers manufactured at the CPFC are sent to Europe to be diced into bars, coated, and then thinned, tested and brought back to Ranovus to complete the rest of the production.

The silicon photonics, designed by Ranovus, come from a foundry in New York State. “Once we get the wafers, we do the testing of all that at our facility and package it in our clean room in Kanata. So the product comes out of Ranovus. This is a made-in-Canada optical engine from Ranovus,” says Arabzadeh.

Ranovus, which sells globally, has just over 100 employees, with about 85 in Ottawa and the rest in Nuremberg, Germany. Arabzadeh expects the company to grow by about 25 percent over each of the next couple of years, primarily in the laser, silicon, photonics, high-speed electronics, digital circuit design, hardware design, firmware design, mechanical design, and advanced packages verticals.

He says Ranovus adds 10 to 12 people a semester by hiring from universities, primarily the University of Ottawa and Carleton, along with the University of British Columbia, McGill, McMaster, and the University of Waterloo.

“I think the biggest attribute locally is the critical mass of talent in Ottawa in this sector,” he says. “There are a lot of companies here, including chip companies, fabless semiconductors, photonics, and systems companies,” notes Arabzadeh.

Arabzadeh says a big challenge in the National Capital Region’s high-tech community is that there needs to be more large Canadian-owned companies. “The majority of the people are hired by multinationals. This is the foundational issue we have in our sector whereby we don’t have enough receptor Canadian-owned companies such that their IP resides in Canada.”

“We need to figure out how to create some more Nortels as opposed to branch offices of multinationals here,” he stresses.

Written By Jeff Buckstein

“I think the biggest attribute locally is the critical mass of talent in Ottawa in this sector,” he says. “There are a lot of companies here, including chip companies, fabless semiconductors, photonics, and systems companies,” notes Arabzadeh.

“I think the biggest attribute locally is the critical mass of talent in Ottawa in this sector,” he says. “There are a lot of companies here, including chip companies, fabless semiconductors, photonics, and systems companies,” notes Arabzadeh.